Three important developments related to rare earth elements (REE) occurred for India in November 2025.

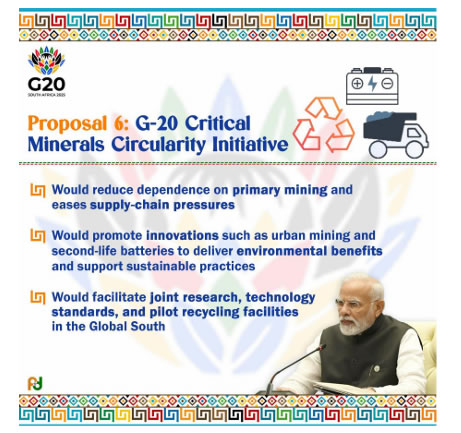

1) G-20 Summit, 22–23 November 2025, Johannesburg, South Africa

Proposal No. 6 at the summit was particularly notable. It focused on Critical Minerals (Rare

Earth Minerals) and emphasized the following circularity initiatives:

a) Reducing pressure on primary mining

b) Promoting urban mining

c) Encouraging joint research on recycling among Global South nations

2) Indian Government Approval of ₹7,280 Crore (~1 Billion USD) for Domestic Rare Earth

Manufacturing

This is a major step forward for India because despite having sufficient rare earth deposits to

meet most of its priority-sector demand, India currently imports almost 100% of its rare earth

requirements

3) Clearance of Long-Pending Investments by BYD, MG, and VinFast in India

The importance of this decision lies in the fact that all three companies possess significant rare

earth resources.

Their entry will support the growth of India’s EV sector by ensuring a smooth supply of rare

earth magnets through in-house production or imports from their home countries therefore

avoiding bottlenecks in the value chain.

These developments in the same month show how serious the rare earth mineral issue is and

how India is taking proactive action in real time to secure her future.

CYCLIC MATERIALS (Canada) is a leading company in rare earth recycling. According to their

published research:

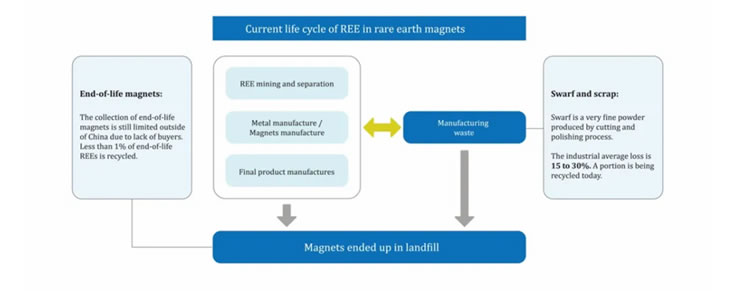

1. Only 1% of rare earth elements are currently recycled globally.

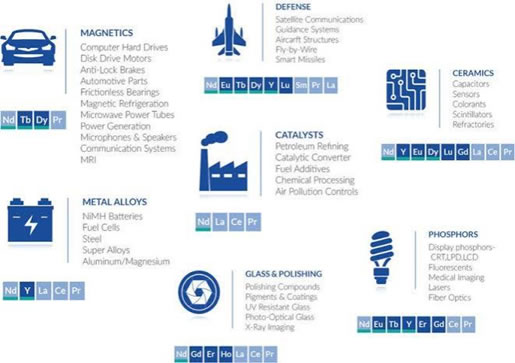

2. Magnets account for 30% of total rare earth usage.

3. McKinsey projects global rare earth demand to grow from 59 kilotonnes in 2022 to

approximately 176 kilotonnes by 2035 which is nearly threefold.

These statistics show that both mining and recycling will have strong markets for decades.

Recycling REEs is nearly as complex as mining them.The quantities present in most electronic

devices are very small and difficult to separate from other materials.

For Example:

A single EV motor contains around 550 grams of rare earths.

An F-35 fighter jet contains approximately 400 kg of rare earth materials (in a 15,000 kg

aircraft).

A simplified chart of the magnet life cycle is shown below:

approach to REE recycling is guided by four key objectives:

1. Environment

2. Economics

3. Employment

4. Energy Efficiency

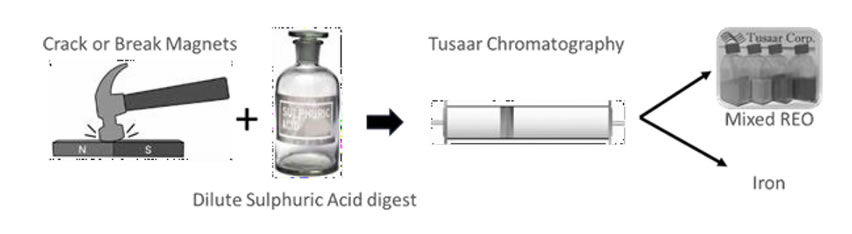

Tusaar Corp has unveiled a rare earth recycling plant with an initial capacity to process 4,000 kg

of magnets per day.This volume alone can supply nearly 10% of the U.S. rare earth demand

through the recycling loop.

Their efficient process involves:

● Mechanical breaking of magnets

● Acid dilution

● A patented chromatography technique

● Separation and recovery

Many more companies are working in the rare earth recycling field. For example:

1. Cyclic Materials

2. Attero Recycling (India)

3. Rare Earth Salts

4. Hitachi Metals

5. Global Tungsten & Powder Corporation

6. Osram

7. Solvay SA

8. Umicore

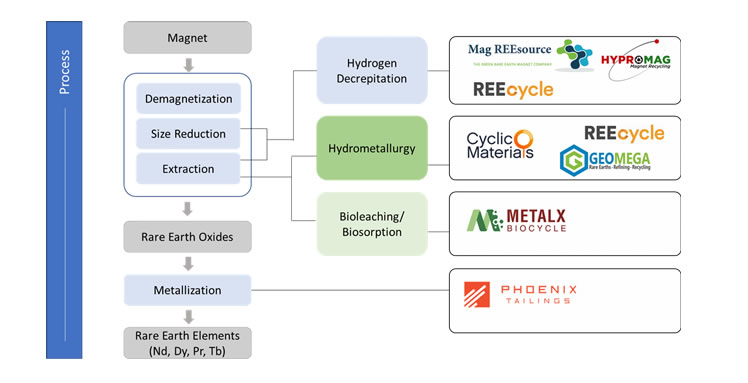

The chart below outlines brief descriptions of REE recycling processes and the techniques used

by leading companies.

Many more recycling companies will enter production, creating a closed-loop circular

ecosystem.

2. EV sales growth will stabilize rather than grow exponentially.

3. Alternatives to rare earths for magnets and batteries will emerge.

We are already observing a slowdown in sales of EVs and solar panels due to oversupply and

price pressure. It’s not that the Rare earth demand will not disappear, but it will stabilize.

The global balance of power will shift and no single country will dominate the REE market

indefinitely.China’s control over rare earths is expected to diminish over the coming decade as

alternative materials emerge.

EVs and consumer electronics are price-sensitive sectors, and prices cannot rise indefinitely. A

more balanced, diversified global rare earth supply chain is taking shape.